Talygen Makes Manufacturing Simpler with Future-Ready Solutions

Since manufacturing companies have started facing a labor shortage, supply delays, and increasing costs, adopting automated solutions has become a great alternative. It helps manufacturing businesses to deliver quick results, eliminate human error, and maximize workflow productivity. That's why Talygen offers future-ready automated project management, asset management, time tracking, and resource scheduling solutions.

Manufacturing Industry Case Study

The Challenges

For several years, the manufacturing company used a traditional approach to practice their workflow operations, including punch clocks to track employees and maintaining manual spreadsheets to manage projects and assets. With the evolving market and increasing competition, the traditional approach fails to keep the company surviving and stepping up over competitors.

The manual approach to managing resources and projects offered low flexibility that kept our manufacturing process slow and outdated. Furthermore, we could not meet project deadlines because of tedious project management operations. As a result, the manufacturing company decided to go online and opt for automation to manage its manufacturing operations effectively.

- Perform repetitive tasks

- Unable to track project status and missed deadlines

- The tedious manual process affects workflow productivity

The Solution

The manufacturing company deployed Talygen's automated solutions and implemented multiple modules to accelerate workflow productivity. Talygen's project management software lets you discover, track, and manage projects on time. The software featured a smart dashboard to get a quick view of the entire project status on a single screen. Moreover, the time tracking suite allows tracking every minute of your workforce across different time zones and maintains operational efficiency.

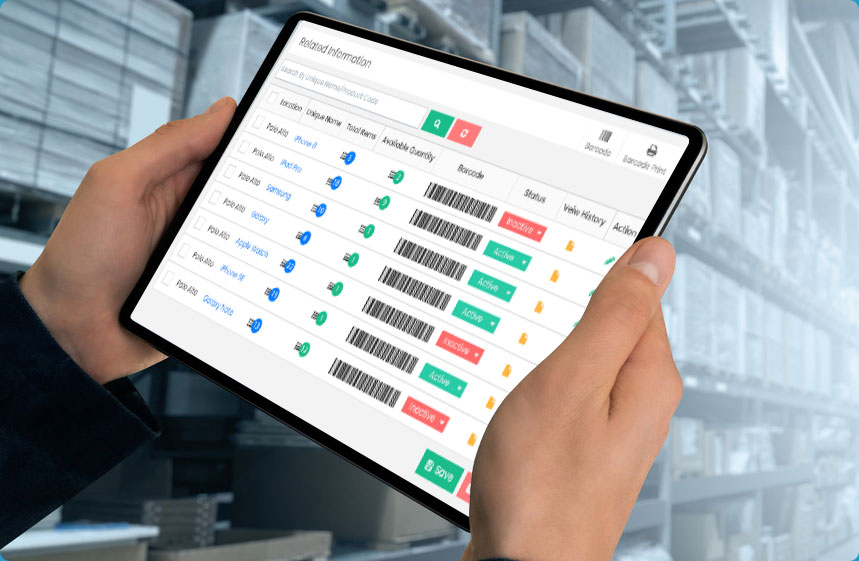

Manufacturing companies also benefit from asset management software to monitor and manage all tangible and intangible assets effectively. It shows a complete picture of the company's asset status and manages the asset management lifecycle. Above all, it proved a cost-effective suite of services that seamlessly manages the entire business operations through a single platform.

- Perform manufacturing tasks with accuracy

- Reduce operating cost

- Improved workplace efficiency

- Automated solutions ensure maximum productivity

The Benefits

- Easy-to-use and flexible solution

- Empower employee productivity with online time tracking

- Eliminate human errors and tedious manual process

- Helps to meet project deadlines and enhance customer experience

- Cost-effective